Ferrington Vineyard Field Trial

Norman Kobler, manager and co-owner of Ferrington Vineyards, was one of the first to participate in the North Coast Soil Health Hub.

The field trial was developed and led by UCCE Advisor Ellie Andrews in partnership with Reyna Yagi of Yagi Sisters Farm. Please reach out to Ellie Andrews with any questions or inquiries.

Ellie Andrews, UC Cooperative Extension

Reyna Yagi, Yagi Sisters Farm

Emilie Winfield, North Coast Soil Hub

Vivian Wauters, UC SAREP California Farm Demonstration Network

Sonja Brodt, UC SAREP California Farm Demonstration Network

Paolo Solari, UC Cooperative Extension Sonoma County Agricultural Technician

Many growers in the North Bay Area demonstrate a clear, long-term commitment to using soil health building practices such as compost, cover crops, and no-till. However, during a Needs Assessment in 2023, many growers expressed that is often economically and physically challenging to use strict no-till soil management practices on their farms all of the time. Farmers often think through the economic and ecological costs and benefits of using tillage at strategic times or in specific locations to help achieve farm goals. They often are faced with difficult decisions and need to balance farmer and farmworker health, labor, economics, and plant and soil health benefits to find an approach that is most appropriate for their unique farm situation.

This case study explores one example that illustrates how a small-scale vegetable grower thought through these tradeoffs that many growers grapple with. Findings offer an opportunity to foster and support open conversations about tillage and low/no-till approaches, farmer decision making processes, and small farm sustainability that integrates soil health and farmer health.

At Yagi Sisters Farm, farmer Reyna Yagi decided to use a walk-behind tractor in 2024 in strategic areas to reduce labor time and physical strain associated with hand-scale no-till practices. With support from the UCCE North Bay Specialty Crops Program, California Farm Demonstration Network and the North Coast Soil Hub, soil health data was collected and labor time and all associated costs were documented. Findings presented here shed light on the early impacts of one BCS tillage pass on soil health metrics and associated costs and benefits. This can help answer growers’ questions about the potential negative impacts of tillage on soil health (for example, “how bad is one strategic BCS pass on soil health? How much time could it save me?”). This work highlights concerns shared by many growers about the need to balance farmer physical health and soil health. Scale-appropriate equipment can serve as an injury and burnout prevention strategy and improve labor efficiency.

Prior soil testing showed high pre-existing soil health at this site before the trial due to its history of careful soil health management.

After implementing the trial, our data suggests only slight reductions in several soil health metrics occurred due to one tillage pass. Compared to no-till soil, the soil where the BCS was used had slightly lower average water stable aggregates, organic matter, CEC, moisture, active carbon, and nutrient levels, though these differences were often quite small. The BCS significantly reduced compaction when measured by resistance via penetrometer, but not when measured by bulk density. Average bulk density, water infiltration rate, respiration, soil texture, pH, and EC were similar between treatments.

Compared to strict hand-scale no-till practices, the BCS saved approximately 1.5 hours of labor per bed, reduced self-reported farmer physical pain and injury by half, and increased on-farm efficiency. However, there was a learning curve associated with using this equipment and mechanic labor shortages and limited parts posed hurdles to implementation.

While this work provides an early look at immediate effects, more data would be required to evaluate how metrics might change over time with regular BCS passes. Multiple tillage passes over time would likely lead to meaningful declines in soil organic matter, nitrogen, water stable aggregates and potentially other soil health metrics, but the rate at which these changes could occur on small-scale diversified vegetable farms in our region is currently unknown.

Benefits: “The upside to the BCS is the reduction in physical labor compared to no till. While I felt fatigued after about 3 hours of using the BCS (they are a different type of physicality and I might add not usually suited to a woman of my size), I completed far more farm work in those 3 hours comparatively. I could complete a field section easily in the span of a day to prep for a big planting rather than prep beds either in a sporadic manner or spanning over a few days depending on managing other farm and job needs. It was incredibly refreshing to see 5-6 beds mounded (often a heavy task by hand) and beds that took minutes to incorporate compost. After a full season of integrating the BCS, I am not experiencing as much shoulder and neck strain and the numbing, pinched nerve issues that would wake me up at night constantly. There still is some pain, but it’s reduced by half in my opinion.”

Tradeoffs: “The downsides to the BCS are my lacking mechanic skills that creates a bigger learning curve and more time at the onset, the fact that I only have one so when a repair came up it took 5 months to repair due to mechanic labor shortages and limited parts availability of the BCS brand so I had to scramble to borrow one on a budget. I’ve also learned that the BCS brand may not be the best fit given that latter downside as that has a big factor in the economics of integrating this machinery into my farm.” – Reyna Yagi, farmer

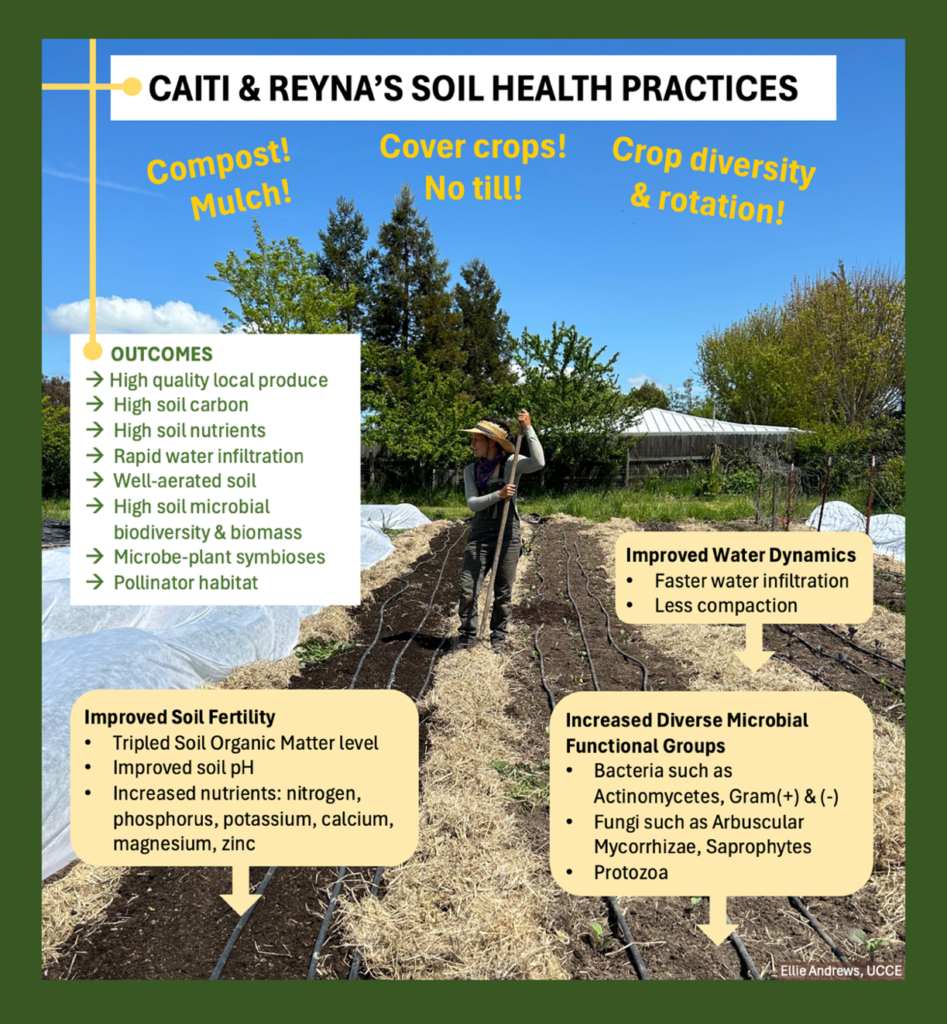

Yagi Sisters Farm is a small-scale diversified vegetable and herb farm located in Sebastopol, California. The farmer, Reyna Yagi, centers ecology, diversity, and localization to serve the community. Previously, Caiti Hachmyer of Red H Farm farmed at this site using agroecological practices including compost, cover crops, and no-till. Reyna has continued implementing these practices to maintain high soil health at this site. Soil testing conducted in 2023 showed that 8 years total of exceptional soil health management by these two farmers led to excellent soil health metrics when compared to nearby uncultivated soil within the same soil type. You can read more about soil sampling and results from 2023 here. Statistics were not performed for the 2023 samples because there were too few samples. However, each soil sample represented aggregated subsamples from within each area of interest.

In early 2024, Reyna expressed the need to explore the strategic use of scale-appropriate soil management equipment to reduce the labor associated with bed preparation in strict no-till farming at the hand-scale. She was interested in soil management strategies for small scale farming that are ergonomic, efficient, and scalable. She expressed the need to balance no/low-till soil health benefits with small farm labor and economic efficiency. This is a key knowledge gap for California small farms, as most of the prior tillage research in our state has focused on conservation tillage in large scale systems which typically have different constraints and opportunities than small farms.

Reyna hypothesized that strategic use of the BCS could help improve farmer bodily health and increase crop rotations rather than increasing land area use. The BCS could reduce the amount of time it takes to transition between harvest of one crop and planting the next. This could allow Reyna to increase total annual yield per area. Assessing how long it takes to do certain tasks for each crop type could help inform crop selection, pricing, and small farm economic sustainability. Comparison charts outlining the tasks, labor, and equipment associated with bed preparation via no-till and via walk-behind tractor are presented in the Results section.

Considering these needs and the lack of data focused on how California small farmers navigate balancing soil health and farmer health, a small field trial was designed and implemented in 2024. The trial goal was to compare the current no-till practices at this farm with one strategic BCS pass and evaluate all associated costs, including the time it takes to transition a bed for new planting, and soil health indicators (listed in methods section) to generate data to help inform on-farm decision making.

Many growers in the North Bay area have expressed the need to prioritize farmer health and well-being in tandem with soil health. Many are thinking through how to strategically incorporate scale-appropriate equipment to support both goals. This case study will provide an example illustrating how one small-scale California farmer is exploring soil health maintenance, strategic tillage, economic sustainability, and strategies to reduce hand labor, risk of farmer burnout, and acute and chronic injury.

Research Question: Can strategic tillage with scale-appropriate equipment in a small no-till vegetable crop system help improve economic efficiency and farmer physical well-being without substantial reductions in soil health?

Hypothesis: Using the walk-behind tractor will likely improve economic efficiency by reducing labor hours, improving farmer physical well-being, and increasing crop rotations due to increased labor inputs. This practice may influence soil health metrics by increasing infiltration rate, reducing bulk density and penetration resistance, increasing nitrate-N, mineralizable N, active C, and respiration. It may reduce SOM, total C and N, and wet aggregate stability. However, after only one tillage pass, differences may be minimal. This data is needed to help answer questions about potential impacts, benefits and tradeoffs.

Field Trial Design:

Treatments:

Design: There were 2 treatments in each block with 4 blocks total for 8 plots (a single treatment-block combination). An experimental unit is one plot. At least 3 soil subsamples from each plot were collected. See Diagram 2 below for design layout. All plots were the same size within a Randomized Complete Block Design. Soil texture is 61% sand, 27% silt, and 12% clay in the field trial area. Reyna continued implementing no-till on many other areas of her farm outside of this trial area.

Methods and Data Collection:

This trial was implemented on June 21, 2024. Soil samples and in-field data were collected on July 2, 2024, after several irrigation events but before the next round of planting. Soil samples were collected using an open-faced auger, mixed in a bucket, placed in plastic bags in a Styrofoam cooler, and sent overnight to the Oregon State University Laboratory. Soil samples were analyzed via the OSU Complete Soil Health Assessment (pH, EC, SOM, total C and N, nitrate-N, P, K, Mg, Ca, texture, mineralizable N, active C, wet aggregate stability, microbial respiration). Three subsamples were aggregated by plot for each soil health metric analyzed by the lab to reduce cost. Eight total soil samples were analyzed, one soil sample per plot.

In the field, water infiltration rate was assessed with a metal ring and penetration resistance was assessed with a penetrometer. Soil samples were collected from the upper 0-6 inches of soil with a metal bulk density ring and mallet, placed in paper bags, oven dried and weighed for soil dry weight per volume. Three subsamples per plot were kept separate for bulk density, infiltration rate, and soil moisture at time of sampling due to low cost of these assessments. Eight subsample locations per plot were taken for penetration resistance due to ease of equipment use. We were able to collect more subsamples for these soil physical metrics due to low cost since they did not require lab analysis. Thus, statistical analyses were performed in R using linear mixed effects models with treatment as a fixed effect and blocks as random using the lmer() command from the lmerTest package. The package ggplot2 was used for all data visualization in R.

Time studies were conducted to assess how long it took to use the BCS walk-behind tractor on each plot. These time lengths were recorded, averaged and used estimated the approximate time it would take to flip an entire 50-foot bed. Reyna provided time estimates for each task associated with flipping a bed via no-till methods, shown in the Results section. The costs of materials, equipment, fuel, maintenance, etc. were found online to provide estimates for no-till and BCS activities.

Soil data collection on July 2, 2024, by Ellie Andrews and Paolo Solari (right photo), UCCE.

Results:

Soil Health Lab Assessments – Fertility and Biological Metrics

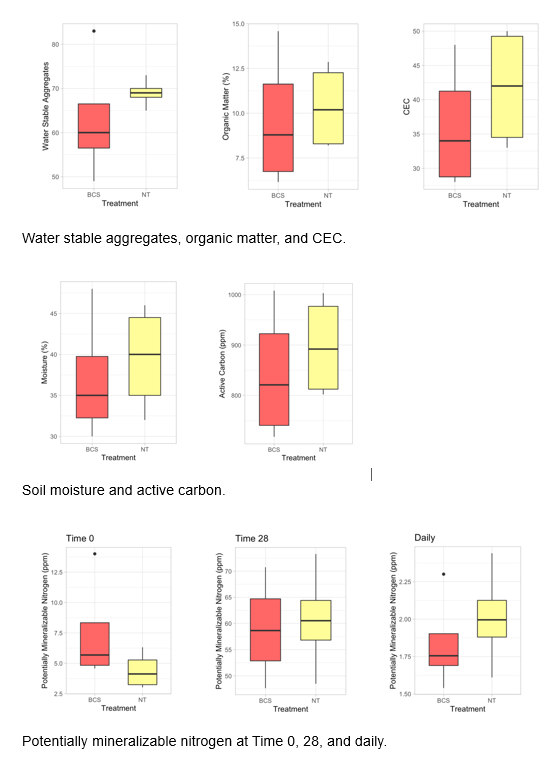

The soil health metrics included in the OSU Complete Soil Health Assessment reflect data from one aggregated soil sample per plot. This data provides a descriptive first look at potential early shifts in soil health after implementation of the BCS. More subsampling would be required to perform statistical analysis. The soil in the BCS treatment had lower average water stable aggregates, organic matter, CEC, moisture, and active carbon, though these differences were slight (figures below). Potentially mineralizable nitrogen was slightly higher in the BCS treatment at Time 0 but lower at Time 28, and the two treatments were similar daily. Average soil phosphorus, potassium, magnesium, and calcium were slightly lower in the BCS soil compared to the No-Till soil. Average respiration, soil texture, pH, and EC were similar between treatments.

Bulk Density, Penetration Resistance and Infiltration Rate as Metrics of Soil Health

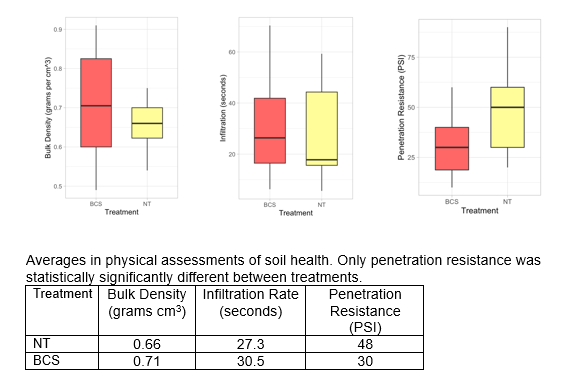

No statistically significant differences in bulk density or infiltration rate were found between treatments. However, penetration resistance was statistically significantly higher in the No-Till soil, indicating that the BCS treatment reduced compaction and aerated the soil.

Labor & Costs

No-till bed preparation equipment costs included hoe ($60) and rake ($40) and associated labor time (see table below). It took an average of 13 seconds to use the walk-behind tractor across one plot. Scaling this up to a 50-foot bed, it would take a little under one minute to prepare a bed. In this trial, the walk-behind tractor saved approximately 1.5 hours of labor per bed by removing the weeding, compost incorporation, and bed shaping steps.

A BCS walk-behind tractor can cost between $2,100 – $7,800 depending on the model and recoil vs. electric start, based on a current internet search. A rear-tine tiller attachment costs approximately $800 (BCS website; https://www.bcsamerica.com/). A BCS can hold approximately 6 liters of fuel; estimated average fuel use was approximately 2 liters per hour at this farm where soil is aerated and easy to work. Any farmer considering a BCS will need to consider maintenance costs, the time required to pick up and transport the equipment, and the time required to learn how to use it if they are new to this equipment. Many small-scale vegetable growers in this region have expressed that equipment co-ownership offers an opportunity for growers to share equipment costs and practical knowledge while lowering risks associated with significant equipment purchases. At this farm, Reyna co-bought the BCS with another local small-scale vegetable farmer to lower the cost to entry and facilitate experimentation with this equipment.

Bed preparation for one 50 ft bed via no-till at this farm took approximately 2 hours.

Task | Labor (minutes) | Equipment |

Weed bed | 35 | Hand, hori hori, fork |

Move straw & drip irrigation aside | 5 | Rake, feet |

Apply compost evenly | 20 | Wheelbarrow, shovel, rake |

Incorporate compost | 45 | Hoe |

Shape bed | 5 | Rake to flatten & shape bed |

Move straw & drip irrigation back onto bed | 5 | Rake, feet |

Bed preparation for one 50 ft bed via a BCS walk behind tractor at this farm took approximately half an hour.

Task | Labor (minutes) | Equipment |

Move straw & drip irrigation aside | 5 | Rake, feet |

Apply compost evenly | 20 | Wheelbarrow, shovel, rake |

Incorporate compost & shape bed | 3 | BCS |

Move straw & drip irrigation back onto bed | 5 | Rake, feet |

Results from this trial were shared with farmers and technical assistance providers at a workshop on March 12, 2025, at Yagi Sisters Farm during the North Coast Soil Hub’s Soil Symposium. The workshop was titled, “Tillage in Small-Scale Annual Cropping Systems: Balancing Farmer Well-being and Soil Health.” The event was led by the North Coast Soil Hub with support from UC Cooperative Extension, California Farm Demonstration Network, Community Alliance with Family Farms (CAFF), and Yagi Sisters Farm. Farmers shared their input about the benefits and limitations of tillage vs. no/low-till approaches during a farmer panel, in small group discussions and by brainstorming with a large notepad. Their input was integrated into the table below that outlines the benefits and limitations of tillage and no/low-till approaches.

Benefits of Tillage: Short term soil structure improvements:

Low labor bed prep:

Weeds & other pests:

| Benefits of No/Low-Till: Long term soil structure improvements:

Costs:

Weeds:

|

Limitations of Tillage: Long term soil degradation with repeated use:

Costs:

Weeds:

| Limitations of No/Low-Till: Bed prep, costs & labor:

Weeds & other pests:

|

Thank you everyone who contributed to this table:

Farmers present at the North Coast Soil Hub’s Soil Symposium workshop at Yagi Sisters Farm

Ellie Andrews, Specialty Crops Advisor, Sonoma, Marin, and Napa Counties

Eddie Tanner, Specialty Crops & Horticulture Advisor, Humboldt, and Del Norte Counties

Krista Marshall, Academic Coordinator, UC Organic Agriculture Institute and Small Farms Network

Jessie Kanter, Academic Coordinator, UC Organic Agriculture Institute and Small Farms Network

Anthony Fulford, Area CE Nutrient Management and Soil Quality Advisor, Merced County

Darryl Wong, Executive Director, Center for Agroecology, UC Santa Cruz

This work provides an example demonstrating how a small-scale farmer used a strategic tillage pass within the confines of her specific farm needs, goals, and farmer health and well-being. With this work, we are not making a statement on where farmers should stand on this issue. This case study can be used to contribute to a larger conversation around balancing soil health and farmer health, acknowledging that every farm and every farmer is unique in terms of constraints, resources, opportunities, and goals.

You can find a downloadable version of the case study summary developed by Ellie Andrews here: Yagi-CFDN-Field-Trial-Summary-3.18.2025

Norman Kobler, manager and co-owner of Ferrington Vineyards, was one of the first to participate in the North Coast Soil Health Hub.

Napa County Gamble Ranch is operated by Treasury Wine Estates and is located within the Oakville AVA in the middle of Napa Valley. The ranch

Napa County Huichica Creek Sustainable Demonstration Vineyard is managed and owned by Napa County Resource Conservation District. Miguel Garcia, NCRCD Sustainable Agriculture Program Manager manages

Our quarterly publication is full of curated and self-published articles sharing our experience, achievements, noteworthy field news, helpful tips, tutorials, and more.